Case Study: Yanmar Mini Excavator Powers Transformation of Austrian Steep-Slope Organic Vineyards for Leo Müller

Case Study: Yanmar Mini Excavator Powers Transformation of Austrian Steep-Slope Organic Vineyards for Leo Müller

Customer Name: Leo Müller

Company Background: As a renowned organic grape grower in Austria, Leo Müller oversees a century-old family winery that boasts a rich heritage of viticulture. Nestled at the foot of the majestic Alps, the winery’s vineyards are celebrated for producing high-quality organic grapes, a reputation built over generations of meticulous farming. However, the unique geographical features of the vineyards—characterized by narrow terraces and steep slopes—have long posed significant operational challenges, prompting Müller to seek innovative solutions for vineyard transformation.

I. Project Challenges and Core Requirements

1. Severe Terrain Restrictions

The vineyard’s terraces feature an average slope of 35°, a steep gradient that makes traditional agricultural machinery completely impractical. Conventional equipment lacks the maneuverability to navigate the narrow terraces and cannot operate stably on such steep inclines, often risking rollovers and damage to the delicate grapevines. Müller’s core requirement was to source small, agile equipment that could balance exceptional flexibility with robust climbing capabilities, enabling seamless operations on the challenging terrain without compromising vine health.

2. Stringent Environmental Protection Standards

As an EU organic certified farm, the winery is obligated to adhere to strict environmental regulations, including low noise emissions and compliance with Euro 5 environmental standards. Additionally, all equipment used on the farm must hold valid CE certification to ensure it meets the European Union’s safety, health, and environmental protection requirements. This further narrowed the scope of suitable equipment, as Müller needed solutions that could deliver operational efficiency while aligning with these rigorous ecological mandates.

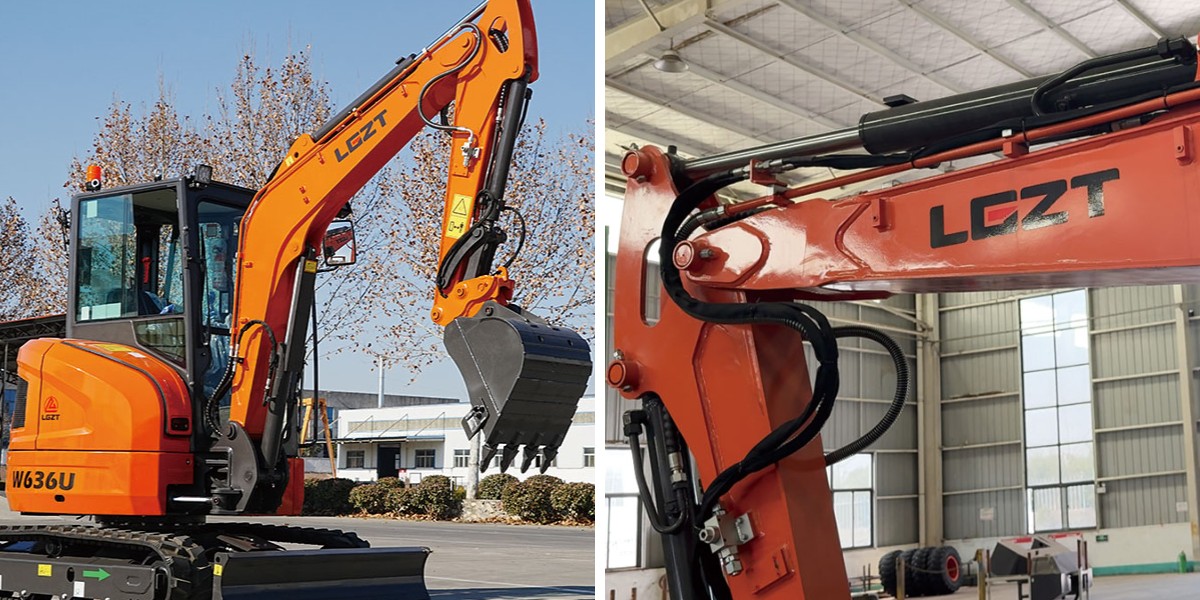

II. LGZT Customized Solution: Precision Equipment Matching with Yanmar Mini Excavator

After in-depth consultations with Müller and a comprehensive assessment of the vineyard’s terrain and regulatory needs, the Lgzt team designed a tailored solution centered around the Yanmar Mini Excavator—a choice driven by the model’s proven performance in challenging, space-constrained environments. Recognizing Müller’s focus on cost-effectiveness alongside quality, the team also provided transparent guidance on Mini Excavator Price and ensured access to reliable Small Excavator For Sale channels, streamlining the procurement process.

• Tailless Rotary Design for Narrow Terrains: The recommended Yanmar Mini Excavator features a tailless rotary structure, a key design advantage that allows it to shuttle effortlessly through the narrow terraces of Müller’s vineyards. Unlike traditional excavators with protruding tails, this model eliminates the risk of colliding with grapevines or terrace edges, ensuring safe and efficient movement even in the most confined spaces.

• Rubber Tracks for Soil and Root Protection: To safeguard the vineyard’s organic soil structure and avoid damaging the delicate grape roots—critical for maintaining organic certification—the Yanmar Mini Excavator is equipped with high-quality rubber tracks. These tracks distribute the equipment’s weight evenly, minimizing soil compaction and reducing the risk of root damage, a key concern for organic viticulture.

• Adaptable Hydraulic System for Integrated Operations: The excavator’s advanced hydraulic system is specially adapted to support integrated trenching and fertilization accessories. This versatility allows Müller’s team to perform multiple tasks—from trenching for irrigation lines to precision fertilization—with a single piece of equipment, eliminating the need for multiple machines and further enhancing operational efficiency.

III. Project Results and Customer Feedback

1. Dramatic Efficiency Improvement

The deployment of the Yanmar Mini Excavator yielded remarkable efficiency gains for the vineyard transformation project. The equipment’s powerful performance and maneuverability enabled a single-day trenching efficiency of 1.8 kilometers, which is 220% higher than the output of the original equipment Müller had used previously. This significant boost in productivity allowed the entire project to be completed 22 days ahead of schedule, translating to approximately 12,000 euros in saved labor costs— a substantial financial benefit for the family-run winery.

2. Outstanding Environmental Value

The Yanmar Mini Excavator also excelled in meeting the winery’s strict environmental requirements. During operation, the equipment’s noise level was consistently below 70 decibels, well within the EU’s low-noise standards, and successfully passed a surprise inspection conducted by the local environmental protection department. Furthermore, the excavator’s reliable design ensured zero hydraulic oil leakage, a critical factor in maintaining the vineyard’s organic soil certification and upholding Müller’s commitment to sustainable farming practices.

3. Glowing Customer Testimonials

Leo Müller expressed immense satisfaction with both the equipment and the support provided by the Lgzt team: “The Lgzt team not only provided the perfect Yanmar Mini Excavator for our steep-slope vineyards but also built a seamless ‘worry-free channel’ from the Chinese factory to our Austrian hillside. Their deep understanding of EU compliance requirements was invaluable—they guided us through every step of the process, helping us avoid potential customs clearance traps that could have delayed the project. What’s more, the stability of the Yanmar Mini Excavator on our 35° terraces even exceeded that of local brands we considered! The transparency around Mini Excavator Price and the accessibility of Small Excavator For Sale options also made the procurement process smooth and stress-free. This partnership has truly transformed our vineyard operations.”

IV. Long-Term Cooperation Prospects

The success of the vineyard transformation project has laid a solid foundation for long-term cooperation between Leo Müller and Lgzt. Building on this positive experience:

1. Leo Müller has already placed an order for two additional Yanmar Mini Excavator units of the same model to support operations in newly acquired vineyard plots, a testament to his trust in the equipment’s performance and reliability.

2. Müller’s enthusiastic recommendation has also generated significant interest in the LGZT solution among his peers in the European viticulture industry, with three other European organic farms expressing clear purchase intentions for the Yanmar Mini Excavator after learning about its success in Müller’s vineyards.

3. To further enhance operational efficiency for mountainous vineyards, the two parties are collaborating on the joint development of mountain-specific harrowing accessories tailored to the Yanmar Mini Excavator. This collaborative effort aims to deepen technical cooperation and create even more specialized solutions for the unique challenges of steep-slope organic viticulture.

If you are interested in Yanmar Mini Excavator, please feel free to contact us. LGZT is a member company of SDLG, dedicated to the research, development, production, and sales of small construction machinery.