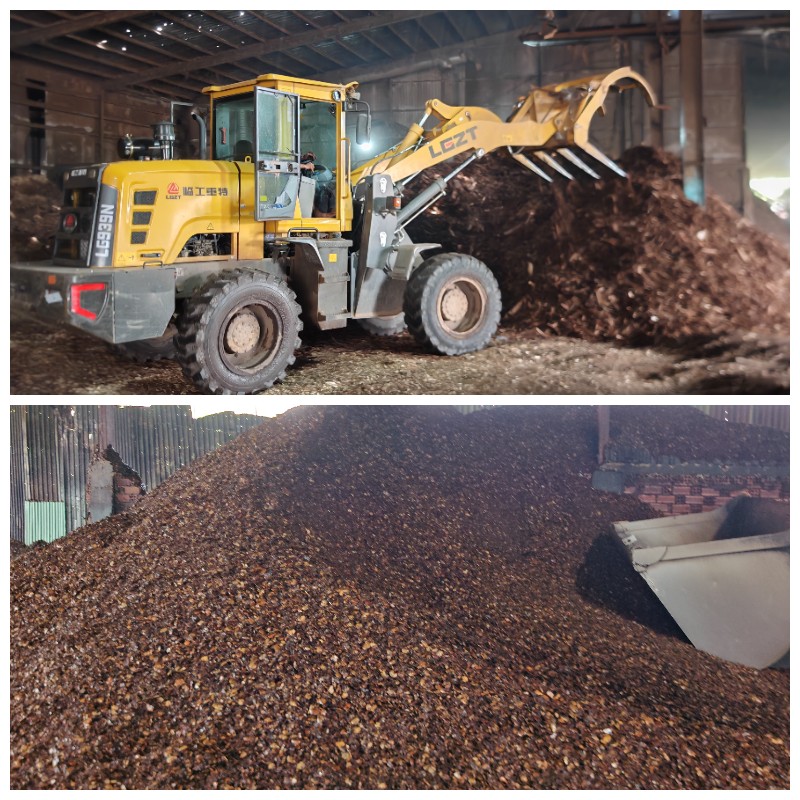

LGZT LG939N Wheel Loader + Pitchfork: An "Efficient Handling Solution" for a Vietnamese Cashew Shell Factory

I. Introduction

Vietnam, the world's largest cashew exporter (accounting for over 60% of global cashew exports), has made its cashew processing industry a vital pillar of its national economy. In Binh Duong Province, Vietnam—an industrial cluster home to 30% of the country's cashew processing companies—the workshops of Vietnam Shunfa Cashew Processing Co., Ltd. are a daily race against time: 50 tons of loose, fluffy cashew shells need to be quickly transported from the processing line to the incinerator or biofuel recovery plant. Any delay directly impacts subsequent production processes.

However, the standard wheel loaders previously used by Shunfa Factory proved a stumbling block in this battle: bucket leaks, awkward turns, and frequent malfunctions kept the factory's efficiency stuck at a low level. It wasn't until January 2025, when the LGZT LG939N wheel loader paired with a customized pitchfork arrived, that this situation was completely changed.

II. Client Background: The Cashew Shell Transportation Dilemma

Shunfa Factory, established in 2010 and located in Thu Dau Mot, Binh Duong Province, Vietnam, is a well-known cashew nut processing company in the region, specializing in cashew kernel extraction and cashew oil refining. With expanded production capacity, the factory's daily cashew nut processing volume has increased from 20 to 50 tons, and its cashew shell production has also soared from 10 to 50 tons. While these cashew shells may appear "useless," they are actually an energy source for the factory. The heat generated by incineration can be used to dry the cashews or be converted into biofuel for sale. The problem was that the light, loose, and brittle nature of cashew nut shells made handling a technically demanding task. The buckets of conventional loaders couldn't effectively gather the shells, and 10-15% would spill with each load, leaving the workshop floor covered in debris that required extra workers to clean. The workshop aisles were only 3.5 meters wide, and the turning radius of conventional loaders was too large, requiring time-consuming back-and-forth adjustments for each U-turn. More critically, the old equipment was five years old, with frequent engine overheating and transmission failures. The equipment required over 10 hours of downtime for maintenance each month, severely impacting production. "We need a loader that understands cashew shells," said Nguyen Minh Cuong, Equipment Supervisor at Thuan Phat. "It needs to be able to securely grasp cashew shells, maneuver flexibly in a narrow workshop, operate continuously for 12 hours without stopping, and help us reduce costs."

III. The Road to Model Selection: From "Comparison" to "Selecting LGZT"

1. On-site Test Drive: The LG939N's "Targeted Advantages"

Arranged by LGZT's Vietnamese distributor, Thuan Phat's drivers and equipment supervisor visited the showroom in Binh Duong Province to test drive the LG939N paired with a pitchfork. During the test drive, two details struck them:

The Pitchfork's Stability: LGZT's customized pitchfork features a "multi-tine + cross-tip" design. The wear-resistant steel tines are evenly spaced, and the tines cross at a 45-degree angle, precisely catching the gaps in the cashew shells and preventing spillage even at high speeds. The driver tried handling a bucket of cashew shells and was very satisfied.

3. Service Guarantee: "The Last Straw"

Beyond the equipment itself, LGZT's service commitment also reassured Shunfa Factory:

The distributor has a parts warehouse in Binh Duong Province, and commonly used parts can be delivered within two hours.

IV. Customer Feedback: "This is exactly the 'cashew shell handling expert' we were looking for."

1. Equipment Supervisor Nguyen Minh Cuong: "It's solved our biggest headaches."

"Our biggest headaches before were spilling cashew shells and equipment malfunctions. Now those problems are gone," said Nguyen Minh Cuong. "The LG939N's pitchfork is so easy to use. It hardly spills, and the workshop floor is much cleaner. It's flexible and turns well, saving us a lot of time. And it's so durable that it can operate for 12 hours straight. We no longer have to work overtime due to equipment failures."

2. Driver Chen Deshun: "It's comfortable to drive and highly efficient."

"I've been driving loaders for 10 years, and this LG939N is the easiest to drive," said Chen Deshun. "The cab is spacious, visibility is excellent, and the operating handle is light, so I can drive for long periods without feeling tired. The control of the pitchfork is very precise; a simple pull of the handle grabs cashew shells, eliminating the need for repeated adjustments. Most importantly, it has plenty of power, so even with a full load of cashew shells, it can easily go uphill."

3. Factory Manager Li Wenhai: "This is a 'worthwhile investment'"

"We were worried about the increased costs of buying new equipment, but now it seems to be a very worthwhile investment," said Li Wenhai. "The LG939N has helped us improve efficiency and reduce costs, and its high reliability allows us to focus on production. We plan to purchase two more LG939Ns to replace the remaining old equipment."

VI. LGZT's "Customer Value Logic"

The Shunfa Factory case is essentially a reflection of LGZT's "customer-centric" product design philosophy. The LG939N wheel loader is not a "general-purpose device" but a customized solution designed for handling light and bulk materials, operating in confined spaces, and requiring high reliability. Its pitchfork, articulated frame, split twin-speed transmission, and large-tank engine—every detail is perfectly suited to Shunfa Factory's cashew nut shell handling needs.

As Mr. Chen, LGZT's Vietnam Sales Manager, puts it, "We don't just sell equipment; we sell 'solutions.' Shunfa Factory's needs are very specific, and our equipment precisely addresses them. This is our core competitiveness."

For Shunfa Factory, the LGZTLG939N is more than just a loader; it's a "cashew nut shell handling expert." It makes the handling process more efficient, cost-effective, and reliable, allowing the factory to focus on its core business (cashew nut processing) rather than being plagued by "handling problems."

As Vietnam's cashew industry continues to expand, we believe that more companies like Shunfa Factory will choose LGZT's customized loader solutions to create "big value" in "small scenarios."