Compact Skid Loader

W707 skid steer loader

Chinese skid steer loader manufacturers

The skid steer loader is of stable and reliable quality

Welcome to visit and inspect the factory

Compact Skid Loader: An Outstanding Example of Multi-Functional Engineering Equipment

On the grand stage of modern engineering construction, various mechanical equipment, like actors, each perform their own duties, jointly presenting a splendid chapter of efficient construction. As a multi-functional engineering equipment, the Compact Skid Loader plays an important role in various engineering scenarios with its unique core features. It is like a jack-of-all-trades in the engineering field, capable of performing outstandingly in various working environments with its outstanding flexibility and versatility. For those seeking Skidloaders For Sale, understanding the comprehensive advantages of this equipment is crucial for making informed purchasing decisions. The following will detail its definition, structure, advantages, application scenarios and technical features, which will also provide valuable references for those concerned about Skid Steer Loader Price and the performance of Small Skidsteers.

Unique Steering Mode

In the traditional field of loaders, the differential has always been a key component for achieving steering. The differential enables the vehicle to turn smoothly by adjusting the speed difference of the wheels on both sides. However, this traditional steering method has certain limitations, especially in narrow Spaces, where its steering flexibility is greatly reduced. The Compact Skid Loader, on the other hand, takes a unique approach. It achieves skid steering by relying on the linear speed difference between the wheels on both sides, discarding the traditional differential—a feature that makesSmall Skidsteers particularly popular in confined working areas.

Imagine that in a warehouse piled high with goods, the space is very narrow. It is extremely difficult for a traditional articulated loader to turn flexibly within it. However, the Compact Skid Loader can handle it with ease. With its unique steering method, it has the ability to steer in place. This feature of turning in place is just like a dancer's wonderful spin on the stage, capable of completing the turning action without much space. Compared with articulated loaders of the same grade, its steering flexibility has been significantly enhanced, which is one of the core selling points for Skidloaders For Sale.

To better understand the advantages of this steering method, we can conduct a comparative experiment. In a simulated narrow working site, articulated loaders of the same grade require a larger space to complete a steering action, and the steering process is relatively slow, requiring multiple adjustments to accurately reach the designated position. The Compact Skid Loader, on the other hand, can quickly complete the steering in place and precisely adjust the direction to rapidly reach the target location. This improvement in steering flexibility gives Skid Steer Loader an incomparable advantage in scenarios such as narrow construction areas on urban streets and cargo handling inside ship holds. For buyers focusing on Skid Steer Loader Price, this practical advantage further enhances the cost-effectiveness of the equipment.

Diverse Driving Forms

The Compact Skid Loader adopts all-wheel drive, providing strong power support for it in different working environments. It offers two chassis designs to choose from: wheeled and tracked. This is just like equipping the equipment with different "shoes" to adapt to various road conditions, a design that makes Small Skidsteers adaptable to more complex working conditions and thus more competitive in the Skidloaders For Sale market.

The wheeled chassis Compact Skid Loader features high traveling speed and strong maneuverability. On flat cement roads or hard ground, the wheeled chassis enables the Skid Steer Loader to move quickly between various operation points, improving work efficiency. It is like a high-performance sports car that can gallop freely under good road conditions. This type of Small Skidsteers is often favored by users engaged in indoor warehouse operations and urban road maintenance.

The crawler model, on the other hand, is tailor-made for special working environments. When encountering muddy or soft ground, the advantages of the crawler model are fully demonstrated. Because the grounding area of the track is larger, it can evenly distribute the weight of the equipment on the ground, reduce the pressure on the ground, and thus prevent the equipment from getting stuck in the mud. Imagine that in the muddy area of a construction site, the equipment with wheeled chassis might get stuck in the soft ground and fail to work properly. The crawler Compact Skid Loader, on the other hand, can move steadily through the mud like a tank and successfully complete various operation tasks. The difference in chassis design also leads to variations in Skid Steer Loader Price, allowing buyers to choose according to their actual needs.

In addition, the crawler model also has an edge in climbing ability. In some mountainous construction sites or operation areas with a certain slope, the crawler Compact Skid Loader can easily climb up the slope and reach the higher operation position by relying on its powerful grip and driving force. This diverse range of drive forms enables Skid Steer Loader to adapt to various complex terrains and working environments, providing more possibilities for engineering construction and increasing the attractiveness of Skidloaders For Sale to a wide range of users.

Compact Body Design

Another notable feature of the Compact Skid Loader is its compact overall size and short wheelbase—this is exactly the core advantage of Small Skidsteers. This is just like a petite and agile athlete who can move freely in a narrow space. This compact body design enables it to easily adapt to narrow Spaces, such as ship cabins, factory interiors, and urban streets, among other working environments, making it a hot-selling type in Skidloaders For Sale.

Inside the cabin, the space is usually very limited and large equipment simply cannot enter. The Compact Skid Loader, on the other hand, can move freely within the cabin with ease to handle the loading, unloading and transportation of goods. It can turn flexibly in narrow passages and accurately place the goods in the designated positions. Inside the factory building, due to the relatively dense placement of equipment and goods, the space is also relatively narrow. The Compact Skid Loader can flexibly shuttle among various equipment and goods, completing the handling and cleaning of materials, and improving the space utilization rate and work efficiency of the factory building. For enterprises with limited operating space, Small Skidsteers have become the first choice, and their Skid Steer Loader Price is also within a reasonable range for most small and medium-sized enterprises.

In the construction of urban streets, due to the heavy traffic flow, the construction sites are often strictly restricted. The compact body design of the Compact Skid Loader enables it to carry out construction operations in narrow Spaces along the street without affecting traffic. For instance, when conducting road maintenance, it can complete tasks such as excavation and backfilling within narrow areas along the roadside without causing significant impact on passing vehicles and pedestrians. The advantage of this compact body design makes the Compact Skid Loader the preferred equipment for operations in narrow Spaces, and also makes Small Skidsteers a popular choice in the Skidloaders For Sale market.

Core Advantage

Multifunctional Working Ability

One of the highlights of the Compact Skid Loader lies in its powerful versatility. It is like a magical toolbox, equipped with all kinds of different tools, which can meet different job requirements. It can quickly replace various accessories such as buckets, forks, breakers and sweepers, and the process can be completed in just a few minutes, thus being able to adapt to different operation requirements such as shoveling, digging, drilling and cleaning. This multifunctional feature is a key factor that affects Skid Steer Loader Price and also makes Skidloaders For Sale more competitive.

In a construction site, the multi-functionality of the Compact Skid Loader was fully demonstrated. During the morning operation, it can be equipped with a bucket to carry out the earthwork transportation work. The excavated soil was quickly loaded into the transport vehicles, which improved the efficiency of earthwork operations. In the afternoon, if drilling operations need to be carried out on the foundation of the building, the operator only needs to spend a few minutes to replace the bucket with a drilling accessory. Then, the Compact Skid Loader can precisely drill the required holes at the designated positions just like a professional drilling device. This versatility makes Small Skidsteers suitable for a variety of engineering scenarios, greatly improving the equipment utilization rate.

In winter snow removal operations on urban roads, Compact Skid Loader can be equipped with sweeper accessories to quickly clear the accumulated snow on the roads. It can clear a smooth road in a short time and ensure the normal operation of urban traffic. This ability to quickly replace accessories enables the Skid Steer Loader to switch rapidly between different operation tasks, significantly enhancing the equipment's utilization efficiency and reducing the cost of engineering construction. For users looking for Skidloaders For Sale, this cost-saving advantage is undoubtedly a crucial consideration when evaluating Skid Steer Loader Price.

Excellent Terrain Adaptability

The all-wheel drive combined with a short wheelbase design of the Compact Skid Loader greatly enhances the equipment's passability on uneven or complex terrains, ensuring efficient operation in all kinds of harsh environments. This is another important advantage that distinguishes Small Skidsteers from other engineering equipment and is also a key selling point in Skidloaders For Sale. Imagine that in a water conservancy construction site in a mountainous area, the terrain is very complex, with steep slopes, muddy gullies and rugged mountain roads. Traditional engineering equipment may struggle to move forward or even fail to work properly in such terrain.

The Compact Skid Loader, with its all-wheel drive and short wheelbase design, has demonstrated outstanding terrain adaptability. All-wheel drive provides the equipment with strong power, enabling it to have sufficient traction when climbing slopes. The short wheelbase design makes the equipment more flexible and enables it to better adapt to changes in terrain. During the climbing process, the Compact Skid Loader can maintain the balance of the vehicle body by adjusting the rotational speed of the wheels on both sides, and climb steadily upwards. When passing through gullies, it can easily cross over with the advantage of its short wheelbase without the vehicle dragging on the ground or getting stuck in the gullies. This strong adaptability makes Skid Steer Loader an indispensable equipment in remote mountainous areas and complex construction sites, and its Skid Steer Loader Price is also recognized by the market for its matching performance.

Furthermore, in the mining operations of some mines, the ground is often covered with crushed stones and potholes. Compact Skid Loader can travel freely in such harsh environments to complete the loading and transportation of ores. Its terrain adaptability makes it a capable assistant in complex terrain operations such as mountainous area construction and mining, providing a strong guarantee for the smooth progress of the projects. For users in mining and other industries who are looking for Skidloaders For Sale, Small Skidsteers with excellent terrain adaptability are undoubtedly the ideal choice.

Typical Application Scenarios

The Field of Industry and Infrastructure

In the industrial and infrastructure sectors, Compact Skid Loader play a significant role due to their flexibility and versatility. During the container clearance operation at the wharf, the interior space of the ship holds at the wharf is small and there are many types of goods. A flexible and operable device is needed for the handling and cleaning of the goods. The compact body design and flexible steering method of the Compact Skid Loader enable it to easily enter the interior of the cabin. After installing the appropriate accessories, it can efficiently complete the loading and unloading of goods and the cleaning of the cabin. This practical application effect makesSkidloaders For Sale more popular in the port logistics industry, and Small Skidsteers are especially favored because of their smaller size.

In terms of warehouse material handling, with the development of the modern logistics industry, the scale of warehouses is getting larger and larger, and the demand for the storage and handling of goods is also increasing day by day. Compact Skid Loader can flexibly move between the shelves in the warehouse and accurately transport goods to the designated positions using fork attachments. Its rapid movement and accurate operation capabilities have greatly enhanced the material handling efficiency of the warehouse and reduced labor costs. For warehouse managers who are concerned aboutSkid Steer Loader Price, the cost-saving effect brought bySmall Skidsteers is very considerable.

Airport runway maintenance is also one of the important application scenarios for Compact Skid Loader. Airport runways need to be maintained and serviced regularly to ensure the safe takeoff and landing of aircraft. During operations such as runway cleaning and de-icing, Skid Steer Loader can be equipped with corresponding accessories to quickly complete various tasks. For instance, when encountering icy and snowy weather in winter, Compact Skid Loader can be equipped with de-icing shovels and salt-spreading equipment to promptly clear the snow and ice on the runway, ensuring the normal operation of the airport. This high-reliability performance makes Skidloaders For Sale highly recognized in the aviation maintenance industry, and the Skid Steer Loader Price is proportional to its high performance.

Municipal Engineering Scene

In municipal engineering scenarios, Compact Skid Loader also play an irreplaceable role. In terms of snow removal on roads, the accumulated snow on urban roads in winter can have a significant impact on traffic. Timely snow removal is the key to ensuring traffic safety. The Compact Skid Loader can be equipped with a sweeper accessory in a short time to quickly clear the snow on the road. It can travel rapidly along the center line of the road, clear the snow to both sides of the road, and open up a safe passage for vehicles and pedestrians. Small Skidsteers are particularly suitable for narrow urban roads, making them an important part of Skidloaders For Sale in municipal procurement.

In the process of cleaning up the residue after asphalt milling, a large amount of residue will be left on the road surface after asphalt milling. If not cleaned up in time, it will affect the quality of subsequent construction. Compact Skid Loader can use bucket accessories to quickly collect the residue and transport it to the designated disposal site. Its efficient cleaning capacity ensures the smooth progress of municipal road construction. For municipal engineering departments that pay attention to Skid Steer Loader Price, the high efficiency and low maintenance cost of Compact Skid Loader make it a cost-effective choice.

Urban crushing operations are also one of the common application scenarios of Compact Skid Loader. In projects such as the demolition of old buildings and road renovation in cities, some concrete structures need to be crushed. The Compact Skid Loader can be equipped with a breaker accessory to accurately crush the target object. Its flexibility enables it to accurately position and operate in the complex urban environment, avoiding unnecessary damage to surrounding buildings and facilities. This safe and efficient operation feature makes Skidloaders For Sale more popular in urban renewal projects, and Small Skidsteers have become the preferred equipment for small-scale crushing operations.

Technical Characteristics

Advanced Transmission System

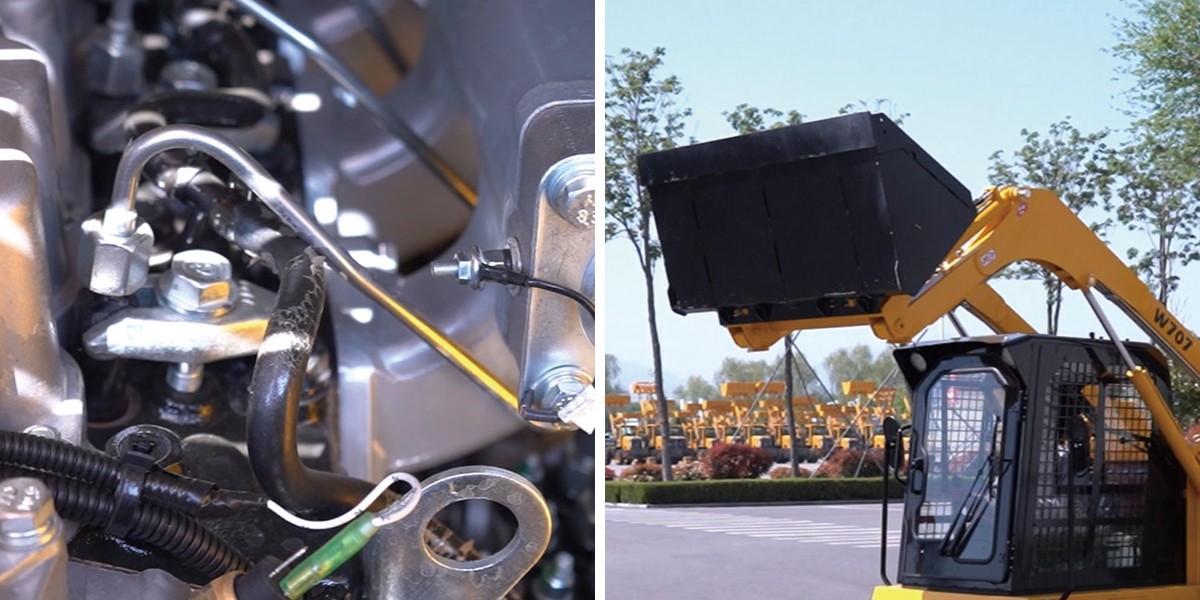

Most Compact Skid Loader adopt dual hydraulic motors and closed hydraulic systems, which are the core components of their advanced transmission systems. This transmission system realizes the integration of service braking, improving the operational stability and convenience of the equipment. The advanced nature of this technology is one of the important factors affecting Skid Steer Loader Price, and it is also a key advantage that makes Skidloaders For Sale stand out in the market.

The dual hydraulic motors provide the Compact Skid Loader with powerful and stable power output. Two hydraulic motors respectively drive the wheels on both sides. Through precise hydraulic control, different rotational speeds of the wheels on both sides can be achieved, thereby realizing flexible steering and efficient driving. Imagine that in a work site that requires frequent steering, the dual hydraulic motors can quickly adjust the rotational speeds of the wheels on both sides according to the steering requirements of the equipment, enabling the equipment to complete the steering action quickly and accurately. This performance advantage makes Small Skidsteers more efficient in frequent operation scenarios.

The closed hydraulic system is the key to ensuring the stability of equipment operation. Compared with open hydraulic systems, closed hydraulic systems have higher efficiency and better sealing performance. It can circulate the hydraulic oil within the system, reducing energy loss and enhancing the working efficiency of the equipment. Meanwhile, the sealing performance of the closed hydraulic system can prevent hydraulic oil leakage, ensuring the reliability and safety of the system. For users purchasingSkidloaders For Sale, the reliability of the transmission system is an important consideration when evaluating Skid Steer Loader Price.

In terms of operational convenience, the integrated design of the service brake enables the operator to control both the driving and braking of the equipment simultaneously through just one operating handle. When it is necessary to stop, the operator only needs to gently press the brake button on the handle, and the equipment can stop quickly. This integrated design simplifies the operation process, reduces the labor intensity of the operators and improves the work efficiency. This user-friendly design makes Compact Skid Loader easier to popularize, and also increases the competitiveness of Skidloaders For Sale.

Safety Design Guarantee

Modern Compact Skid Loader focus on operational safety, providing operators with a safer and more comfortable working environment. The fully enclosed cab is an important component of its safety design. The fully enclosed cab can effectively isolate external noise, dust and bad weather, creating a quiet and clean working space for the operator. Imagine that in a dusty construction site, operators are sitting in a fully enclosed cab, protected from dust and able to focus on operating the equipment. This safety feature is also an important part of the value embodiment of Skid Steer Loader Price, and is highly valued by users when choosing Skidloaders For Sale.

Shock absorption devices are also an important measure to ensure the safety and comfort of operators. During the operation of the equipment, the shock absorption device can effectively reduce the impact of vibration on the operators. Whether driving on rough terrain or performing high-intensity operations, shock absorption devices can provide operators with a smooth driving experience, reducing the risk of fatigue and physical injury. For Small Skidsteers, which are often used in complex terrains, the shock absorption design is particularly important to ensure the long-term stable operation of operators.

The optimized field of vision design enhances the operational safety of the operators. Through reasonable cab layout and window design, operators can obtain a wider field of vision and clearly observe the situation around the equipment. When performing operations, operators can promptly identify obstacles and people around them, thus avoiding collision accidents. This safety design guarantee not only protects the life safety of the operators, but also improves the overall working efficiency and reliability of the equipment. For enterprises that pay attention to safe production, this is an important factor to consider when purchasing Skidloaders For Sale, and it also makes the Skid Steer Loader Price more reasonable in terms of safety value.