Electric Small Wheel Loader

1. Pure electric wheel loader

2. Zero emission, no pollution

3. China source manufacturer, complete export qualifications

4. Recruiting agents worldwide, welcome to leave a message for consultation

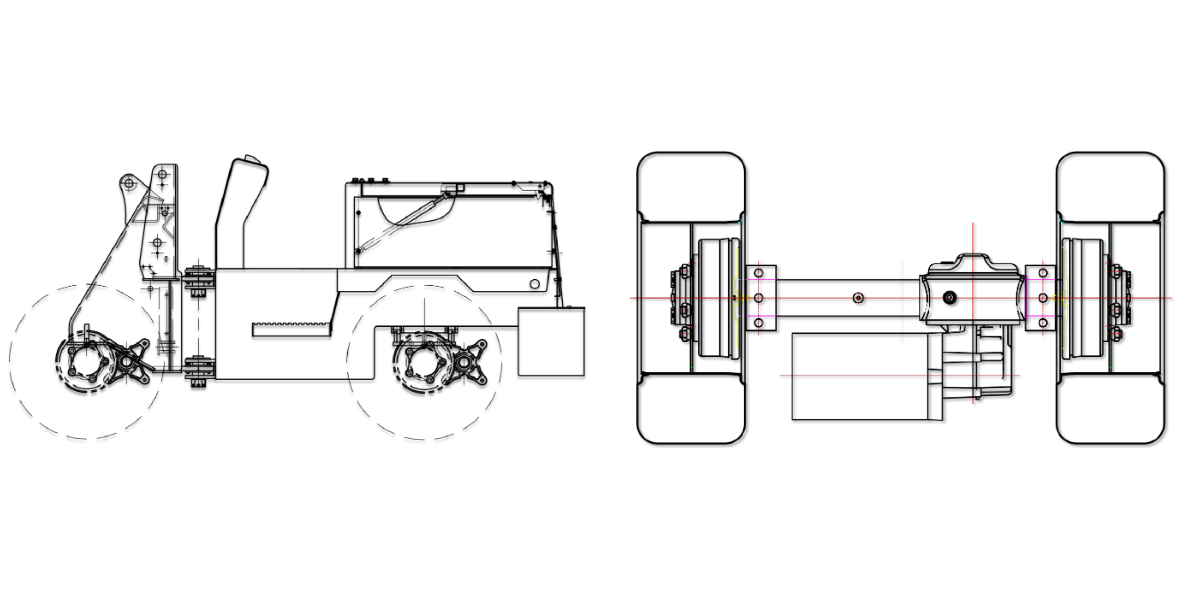

The WE905 electric loader adopts the mature dual-bridge dual-motor drive solution on the market, with the characteristics of high transmission efficiency, low parasitic power, fast acceleration, and high working efficiency; the working device adopts the company's LG918F mature model for optimization and reduction, with the characteristics of large lifting capacity, good automatic leveling performance, and stable operation; articulated frame, full hydraulic steering; front and rear frames, using the traditional loader structure solution, reasonable force, good reliability; optimize the control strategy of traction motor and hydraulic pump motor, reduce unnecessary energy waste, and further improve its endurance; power battery is equipped with high-performance ternary lithium battery and optimized BMS management system.

The main features of the WE905 electric loader model are the use of pure electric chassis, no pollution, zero emissions, low noise, good vehicle control performance, and low operating costs

LCD Instrument Panel | Intelligent Fast Charging Vehicle Mounted Charger | Ternary Polymer Lithium Battery |

The front and rear frames of the WE905 electric loader are articulated frames, fully hydraulic steering, and adopt the traditional plate-type welded structure of loaders. It has the characteristics of reasonable force, compact structure and high reliability. | The WE905 electric loader transmission system adopts a front and rear axle dual drive system, and the drive motor is directly installed on the bridge. The system has the characteristics of high transmission efficiency, small parasitic power, fast speed increase and high working efficiency. |

WHEEL LOADER SPECIFICATIONS

ITEM | SPECIFICATIONS | UNIT | ||

Rated loading capacity | 500 | kg | ||

Capacity of bucket | Horizontal loading | 0.18 | m3 | |

Vertical loading | 0.25 | m3 | ||

Working weight | 1200 | kg | ||

Dumping height | 1850 | mm | ||

Dumping distance | 573 | mm | ||

Working time | Lifting | 6.4 | s | |

Decling | 3.6 | s | ||

Dumling | 1.7 | s | ||

Max.Speed | Forward | 16 | km/h | |

Reverse | 16 | km/h | ||

Max. traction force in each gear | Forward | 8.5 | kN | |

Reverse | 8.5 | kN | ||

Max. Gradeability | 45 | % | ||

Min. turning radius | Outside of bucket | 3344 | mm | |

The inner side of the loader body | 1838 | mm | ||

Overall dimensions | Machine length | 3206 | mm | |

Machine height | 1506/2072 | mm | ||

Machine width | 1056 | mm | ||

Width of bucket | 1200 | mm | ||

Wheel base | 1300 | mm | ||

Wheel spacing | 840 | mm | ||

Max. steering angle (Left/Right) | 30 | ° | ||

Min. ground clearance | 195 | mm | ||

Departure angle | 30 | ° | ||

Lateral swing angle of subframe (±) | 6 | ° | ||

Excavation depth (bucket tilt forward 10 °) | 90 | mm | ||

Company Strength:

Founded in 2013, LGZT has been committed to the research, development, manufacturing, sales, and service of high-cost-performance small construction machinery. The company has successively been awarded as a National "Specialized, Refined, Unique, and Innovative" Little Giant Enterprise, a National High-tech Enterprise, a Shandong Province Quality Brand, and a Shandong Province Manufacturing Single-item Champion. It currently offers six major product series, including ZL, LG, W, WE, export-oriented, and all-terrain forklifts, with more than 1,000 varieties in total. These products are exported to over 20 countries and regions, including Russia, Australia, and Vietnam.

The company is dedicated to continuously manufacturing reliable products and providing considerate and high-quality services to help global customers create greater value. It was the first in the country to apply car manufacturing processes to the production of small construction machinery. Equipped with the most advanced electrophoretic shot blasting and powder coating production lines in China, the company has achieved a green transformation from traditional oil-based paints and water-based paints to powder coating processes, completely solving the VOC pollution problem and addressing issues such as easy rusting and fading of small construction machinery.