1.5T Wheel Loader

LG933F Wheel Loader

Working device

1. It adopts reinforced standard bucket with good wear-resisting performance and high shoveling efficiency, and the scientifically designed automatic leveling technology simplifies the operation process and reduces the driver's labor intensity.

2. It adopts 100/60 turning cylinder and 90/50 lifting cylinder, the digging force can reach 30KN, and the three items and time are short, which effectively improves the working efficiency.

Innovative technology application

The parts adopt electrophoretic spraying, which can effectively prevent the corrosion and rust of metal parts in the harsh environment, and improve the overall durability and service life of the product.

The LG933F Wheel Loader is a reliable 1.5T wheel loader built for small to mid-sized projects. Whether you're working in construction, agriculture, municipal maintenance, or material handling, this machine is compact, powerful, and super efficient. It's perfect for tight spaces and gets the job done fast—whether it's site leveling, loading, or transporting materials.

What makes the LG933F Wheel Loader stand out is its smart design. It focuses on lightweight construction, flexible operation, and low fuel consumption—all while being easy to maintain. Plus, thanks to its modular attachment system, this 1.5T wheel loader can easily switch between tools like buckets, forks, or sweepers, giving you a versatile solution that adapts to your project's needs.

Performance Parameters:

Items | Parameters | Items | Parameters |

Minimum turning radius(mm) | 5240 | Bucket width(mm) | 2135 |

Theoretical climbing capacity(°) | 25 | Wheelbase(mm) | 2420 |

Maximum traveling speed(Km/h) | 33 | Three items and time(s) | 10.4 |

Minimum traveling speed(Km/h) | 5 | Maximum rising power(kN) | ≥30 |

Maximum unloading height(mm) | 3560 | Bucket capacity(m³) | 0.87 |

Unloading distance(mm) | 790 | Combined working condition(KN) | |

Maximum traction force(KN) | 47 | Bucket width(mm) | 27 |

Dimensions And Weight Parameters:

Items | Parameters | Items | Parameters | |

Length(mm) | 6350 | Minimum Ground Clearance(mm) | 370 | |

Height(mm) | 2950 | Wheelbase(mm) | 1560 | |

Width(mm) | 2135 | |||

Weights | Rated loading mass (kg) | 1500 | ||

Whole machine weight(without person)Kg | 5575 | |||

Engines:

Items | Parameters | Items | Parameters |

Model | YN38TRF4 | Number of cylinders | 4 |

Manufacturer | YunNei | Bore/stroke (mm) | 102*115 |

Rated power(/kW) | 36.8 | Minimum Fuel Consumption Rate(g/kW.h) | ≤235 |

Rated speed(r/min) | 2400 | Maximum torque(N.m) | 237 |

Displacement (L) | 3.76 | ||

Transmission System:

Items | Parameters |

Type | 265 split double height |

Transmission Gear | Front 4 Rear 4 |

Brake Type | Air Brake |

Axle | Center wheel side axle |

Tire Model | 16/70-20 |

Front wheel air pressure (Mpa) | 0.33 |

Rear wheel air pressure (Mpa) | 0.30 |

Steering System:

Items | Parameters |

Type | Fully hydraulic steering |

Steering angle(°) | 33 |

System working pressure (Mpa) | 16 |

Fuel Capacity:

Items | Parameters | Items | Parameters |

Fuel oil (L) | 84L | Engine(L) | 6.8 |

Hydraulic Oil (L) | 84L | Transmission (L) | 22 |

Bridge (L) - Single | 14L | Brake System(L) | 1.5 |

Product Details:

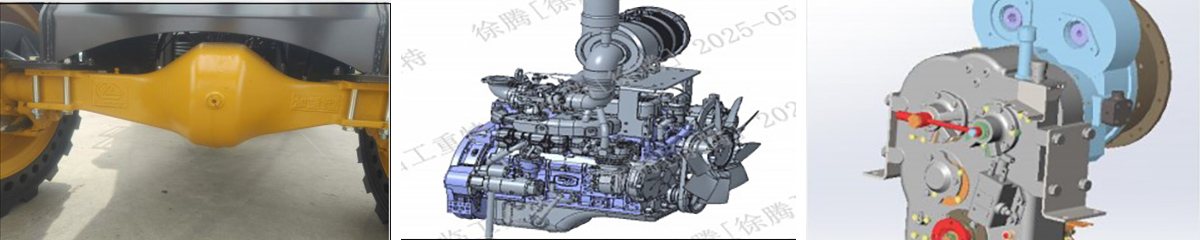

Engine

1. Equipped with Yunnei YN38GBZ engine, with 76Kw power and 340N.m torque, strong power and large torque reserve, it can easily cope with all kinds of heavy-duty operations.

2. Adopting high-efficiency supercharger, the supercharger response speed is fast, the air intake is sufficient, and the combustion is more complete.

3. It can output peak torque at 1200-1800rpm, reducing ineffective fuel consumption and suitable for loaders with frequent starting and stopping and low-speed operation.

Transmission system

1.265 split gearbox is adopted to reasonably match the transmission speed ratio, which can effectively transfer power and improve the traction performance and acceleration performance of the loader.

2.265 split gearbox adopts fixed-axis power shift, gear shift is four-in-four-out, fixed-axis, hydraulic shift, easy operation, smooth gear shift, reducing the cost of later use and maintenance difficulties.

3. Through the design of wheel-side reducer, it can significantly improve the carrying capacity, which can meet the demand of the loader in handling heavy loads and adapt to heavy-duty working conditions.

4. With 16/70-20 tires, it has large grounding area, good grip, and good passability, and can drive stably in both rugged construction sites and soft fields.

Performance Features: Comfort

(1) The cab is designed according to ergonomics, with spacious space and wide field of vision, which can effectively reduce the driver's visual blind spot and work fatigue.

2) The airbag seat can be automatically adjusted according to the driver's weight and road conditions, with good shock absorption effect, which can reduce the impact of bumps on the driver's body, and it is not easy to feel fatigue in long time operation.

3) The cab has good sealing, effective dustproof and sound insulation, which improves the operation comfort, reduces the interference from the outside environment and enhances the operation safety.

4) Optional heating and cooling air conditioning can create a comfortable working environment for the driver, no matter in the hot summer or cold winter, it can keep the driver in a good working condition and improve the working efficiency and comfort.

Company Strength:

Founded in 2013, LGZT has been committed to the research, development, manufacturing, sales, and service of high-cost-performance small construction machinery. The company has successively been awarded as a National "Specialized, Refined, Unique, and Innovative" Little Giant Enterprise, a National High-tech Enterprise, a Shandong Province Quality Brand, and a Shandong Province Manufacturing Single-item Champion. It currently offers six major product series, including ZL, LG, W, WE, export-oriented, and all-terrain forklifts, with more than 1,000 varieties in total. These products are exported to over 20 countries and regions, including Russia, Australia, and Vietnam.

The company is dedicated to continuously manufacturing reliable products and providing considerate and high-quality services to help global customers create greater value. It was the first in the country to apply car manufacturing processes to the production of small construction machinery. Equipped with the most advanced electrophoretic shot blasting and powder coating production lines in China, the company has achieved a green transformation from traditional oil-based paints and water-based paints to powder coating processes, completely solving the VOC pollution problem and addressing issues such as easy rusting and fading of small construction machinery.